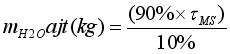

Agri-food processing emits huge quantities of waste and is considered one of today's major environmental problems. There are many different options (anaerobic digestion, thermochemistry and feed production) that can be applied to the management and evaluation of waste treatment. The aim of the present study was to explore the appropriate recovery option for Adansonia digitata seed cake through its characterization. The physicochemical characteristics of Adansonia digitata seed cakes were determined in accordance with international standards. Anaerobic digestion was tested under thermophilic conditions in batch mode over 75 days. Results showed that dry matter content averaged 87.35 ± 0.03%, organic matter content averaged 95.03 ± 0.41%, carbon to nitrogen ratio averaged 19.75. Digestion of Adansonia digitata seed cakes proved highly productive, with a maximum percentage of 68.5% CH4 for 185.57 liters of biogas, i.e. an average production of 2.47 liters per day for 1720 g DM. The methanogenic potential (BMP) of Adansonia digitata seed cake was 331.21 ml/g of organic matter introduced. Adansonia digitata oilcake had an average gross calorific value of 18.54MJ/Kg. These results are encouraging and mark the start of any study on the energy recovery of Adansonia digitata seed cake in biogas.

| Published in | Science Journal of Energy Engineering (Volume 12, Issue 3) |

| DOI | 10.11648/j.sjee.20241203.14 |

| Page(s) | 59-66 |

| Creative Commons |

This is an Open Access article, distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution and reproduction in any medium or format, provided the original work is properly cited. |

| Copyright |

Copyright © The Author(s), 2024. Published by Science Publishing Group |

Adansonia digitata, Biomass, Characterization, Energy

(1)

(1)  (2)

(2)  (3)

(3)  (4)

(4)  (5)

(5)  (6)

(6)  (7)

(7) Parameters | Baobab cake | Standard deviation |

|---|---|---|

pH | 5.5 | - |

N (%) | 2.74 | - |

C/N | 19.75 | - |

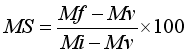

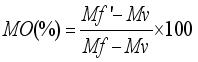

MO (%) | 95.03 | 0.41 |

Dryness (%) | 87.35 | 0.03 |

Total solids (%) | - | - |

Total volatile solids (%) | - | - |

Total carbon (%) | 54.03 | - |

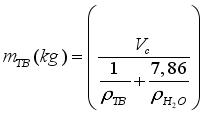

ρ (kg/l) | 1.45 | 0.29 |

Higher Heating Value (HHV) (MJ/kg) | 18.43 | 0.37 |

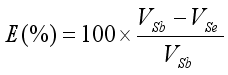

MO (%) | Efficiency (%) | |

|---|---|---|

input | output | |

88.90 | 73.03 | 17.98 |

BMP | Biomethane Potential |

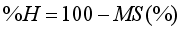

MO | Organic Metter |

| [1] | F. Xu and Y. Li, “Solid-state co-digestion of expired dog food and corn stover for methane production,” Bioresour. Technol., vol. 118, pp. 219–226, 2012, |

| [2] | C. Morales-Polo, M. del Mar Cledera-Castro, and B. Yolanda Moratilla Soria, “Reviewing the anaerobic digestion of food waste: From waste generation and anaerobic process to its perspectives,” Appl. Sci., vol. 8, no. 10, 2018, |

| [3] | A. Neri, B. Bernardi, G. Zimbalatti, and S. Benalia, “An Overview of Anaerobic Digestion of Agricultural By-Products and Food Waste for Biomethane Production,” Energies, vol. 16, no. 19, 2023, |

| [4] | H. Ofori, A. Bart-Plange, A. Addo, and K. A. Dzisi, “Impact of Different Oil Extraction Techniques on the Physicochemical Properties of Adansonia digitata Seed,” Int. J. Food Sci., vol. 2023, 2023, |

| [5] | M. K. Gafar, A. U. Itodo, A. A. Warra, and M. O. Udo, “Extraction and physicochemical characterization of baobab (Adansonia digitata) seed oil,” NSUK J. Sci. Technol., vol. 2, no. 1, pp. 1–8, 2012. |

| [6] | I. S. Asogwa, A. N. Ibrahim, and J. I. Agbaka, “African baobab: Its role in enhancing nutrition, health, and the environment,” Trees, For. People, vol. 3, no. October 2020, p. 100043, 2021, |

| [7] | P. M. Dass, W. L. Danbature, and E. Karu, “EXTRACTION and BIODEGRADATION OF BAOBAB (Adansonia digitata) SEEDS OIL BY FUNGI (Aspergillus niger),” vol. 3, no. 5, pp. 128–137, 2013. |

| [8] | R. Roy, L. Haak, L. Li, and K. Pagilla, “Anaerobic digestion for solids reduction and detoxification of refinery waste streams,” Process Biochem., vol. 51, no. 10, pp. 1552–1560, 2016, |

| [9] | I. S. Horváth, M. Tabatabaei, K. Karimi, and R. Kumar, “Recent updates on biogas production - A review,” Biofuel Res. J., vol. 3, no. 2, pp. 394–402, 2016, |

| [10] | R. Gaulier and H. Serres, “Composition en acides aminés de quelques tourteaux de Madagascar,” Rev. d’élevage médecine vétérinaire des pays Trop., vol. 24, no. 1, p. 137, 1971, |

| [11] | H. Xu et al., “Effect of microaerobic microbial pretreatment on anaerobic digestion of a lignocellulosic substrate under controlled pH conditions,” Bioresour. Technol., vol. 328, no. February, pp. 1–9, 2021, |

| [12] | J. C. Mabala, “Aptitude d’ écosystèmes anaérobies industriels à produire du méthane à partir d’ éthanol en conditions psychrophile, mésophile et thermophile,” UNIVERSITE DE MONTPELLIER II, MONTPELLIER SUPAGRO, 2012. |

| [13] | S. M. King, S. Barrington, and S. R. Guiot, “In-storage psychrophilic anaerobic digestion of swine manure: Acclimation of the microbial community,” Biomass and Bioenergy, vol. 35, no. 8, pp. 3719–3726, 2011, |

| [14] | I. Konkol, L. Świerczek, and A. Cenian, “Chicken Manure Pretreatment for Enhancing Biogas and Methane Production,” Energies, vol. 16, no. 14, 2023, |

| [15] | M. H. Abd-Alla, F. M. Morsy, and A. W. E. El-Enany, “Hydrogen production from rotten dates by sequential three stages fermentation,” Int. J. Hydrogen Energy, vol. 36, no. 21, pp. 13518–13527, 2011, |

| [16] | A. K. Sharma, P. K. Sahoo, M. Mukherjee, and A. Patel, “Assessment of Sustainable Biogas Production from Co-Digestion of Jatropha De-Oiled Cake and Cattle Dung Using Floating Drum Type Digester under Psychrophilic and Mesophilic Conditions,” Clean Technol., vol. 4, no. 2, pp. 529–541, 2022, |

| [17] | Prayitno and S. Rulianah, “Production of biogas using AnF2B reactor from cassava starch wastewater with consortium bacteria as biocatalyst,” IOP Conf. Ser. Earth Environ. Sci., vol. 969, no. 1, pp. 2–8, 2022, |

| [18] | H. Jiang, Y. Qin, S. I. Gadow, A. Ohnishi, N. Fujimoto, and Y. Y. Li, “Bio-hythane production from cassava residue by two-stage fermentative process with recirculation,” Bioresour. Technol., vol. 247, pp. 769–775, 2018, |

| [19] | L. R. S. Andrade et al., “Oyster shell-based alkalinization and photocatalytic removal of cyanide as low-cost stabilization approaches for enhanced biogas production from cassava starch wastewater,” Process Saf. Environ. Prot., vol. 139, pp. 47–59, 2020, |

| [20] | L. Awhangbo, “Suivi et contrôle de la digestion anaérobie à partir de la SPIR et de la production de biogaz : Évaluation des méthodes chimiométriques adaptées,” Université de RENNES1, 2019. |

APA Style

Haro, K., Nourou, A. A. S. K., Sandwidi, S., Compaore, A., Tubreoumya, G. C., et al. (2024). Characterization of Adansonia Digitata Seed Cake with a View to Identifying an Energy Recovery Strategy. Science Journal of Energy Engineering, 12(3), 59-66. https://doi.org/10.11648/j.sjee.20241203.14

ACS Style

Haro, K.; Nourou, A. A. S. K.; Sandwidi, S.; Compaore, A.; Tubreoumya, G. C., et al. Characterization of Adansonia Digitata Seed Cake with a View to Identifying an Energy Recovery Strategy. Sci. J. Energy Eng. 2024, 12(3), 59-66. doi: 10.11648/j.sjee.20241203.14

AMA Style

Haro K, Nourou AASK, Sandwidi S, Compaore A, Tubreoumya GC, et al. Characterization of Adansonia Digitata Seed Cake with a View to Identifying an Energy Recovery Strategy. Sci J Energy Eng. 2024;12(3):59-66. doi: 10.11648/j.sjee.20241203.14

@article{10.11648/j.sjee.20241203.14,

author = {Kayaba Haro and Abdel Anziph Sergel Khalid Nourou and Sayouba Sandwidi and Abdoulaye Compaore and Guy Christian Tubreoumya and Antoine Bere and Oumar Sanogo},

title = {Characterization of Adansonia Digitata Seed Cake with a View to Identifying an Energy Recovery Strategy

},

journal = {Science Journal of Energy Engineering},

volume = {12},

number = {3},

pages = {59-66},

doi = {10.11648/j.sjee.20241203.14},

url = {https://doi.org/10.11648/j.sjee.20241203.14},

eprint = {https://article.sciencepublishinggroup.com/pdf/10.11648.j.sjee.20241203.14},

abstract = {Agri-food processing emits huge quantities of waste and is considered one of today's major environmental problems. There are many different options (anaerobic digestion, thermochemistry and feed production) that can be applied to the management and evaluation of waste treatment. The aim of the present study was to explore the appropriate recovery option for Adansonia digitata seed cake through its characterization. The physicochemical characteristics of Adansonia digitata seed cakes were determined in accordance with international standards. Anaerobic digestion was tested under thermophilic conditions in batch mode over 75 days. Results showed that dry matter content averaged 87.35 ± 0.03%, organic matter content averaged 95.03 ± 0.41%, carbon to nitrogen ratio averaged 19.75. Digestion of Adansonia digitata seed cakes proved highly productive, with a maximum percentage of 68.5% CH4 for 185.57 liters of biogas, i.e. an average production of 2.47 liters per day for 1720 g DM. The methanogenic potential (BMP) of Adansonia digitata seed cake was 331.21 ml/g of organic matter introduced. Adansonia digitata oilcake had an average gross calorific value of 18.54MJ/Kg. These results are encouraging and mark the start of any study on the energy recovery of Adansonia digitata seed cake in biogas.

},

year = {2024}

}

TY - JOUR T1 - Characterization of Adansonia Digitata Seed Cake with a View to Identifying an Energy Recovery Strategy AU - Kayaba Haro AU - Abdel Anziph Sergel Khalid Nourou AU - Sayouba Sandwidi AU - Abdoulaye Compaore AU - Guy Christian Tubreoumya AU - Antoine Bere AU - Oumar Sanogo Y1 - 2024/09/20 PY - 2024 N1 - https://doi.org/10.11648/j.sjee.20241203.14 DO - 10.11648/j.sjee.20241203.14 T2 - Science Journal of Energy Engineering JF - Science Journal of Energy Engineering JO - Science Journal of Energy Engineering SP - 59 EP - 66 PB - Science Publishing Group SN - 2376-8126 UR - https://doi.org/10.11648/j.sjee.20241203.14 AB - Agri-food processing emits huge quantities of waste and is considered one of today's major environmental problems. There are many different options (anaerobic digestion, thermochemistry and feed production) that can be applied to the management and evaluation of waste treatment. The aim of the present study was to explore the appropriate recovery option for Adansonia digitata seed cake through its characterization. The physicochemical characteristics of Adansonia digitata seed cakes were determined in accordance with international standards. Anaerobic digestion was tested under thermophilic conditions in batch mode over 75 days. Results showed that dry matter content averaged 87.35 ± 0.03%, organic matter content averaged 95.03 ± 0.41%, carbon to nitrogen ratio averaged 19.75. Digestion of Adansonia digitata seed cakes proved highly productive, with a maximum percentage of 68.5% CH4 for 185.57 liters of biogas, i.e. an average production of 2.47 liters per day for 1720 g DM. The methanogenic potential (BMP) of Adansonia digitata seed cake was 331.21 ml/g of organic matter introduced. Adansonia digitata oilcake had an average gross calorific value of 18.54MJ/Kg. These results are encouraging and mark the start of any study on the energy recovery of Adansonia digitata seed cake in biogas. VL - 12 IS - 3 ER -